Intake Testing

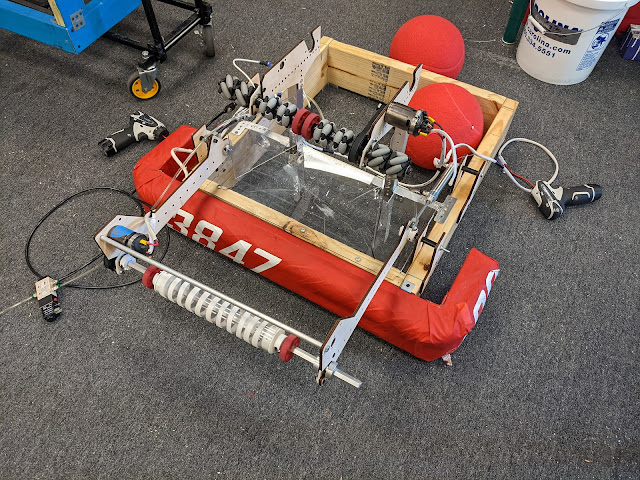

We started on a more complete intake test rig with bumpers and more adjustability.

We are using silicone bands in this video, soft silicone has worked well in our past intakes (2019) and it appears to grip the balls well this year.

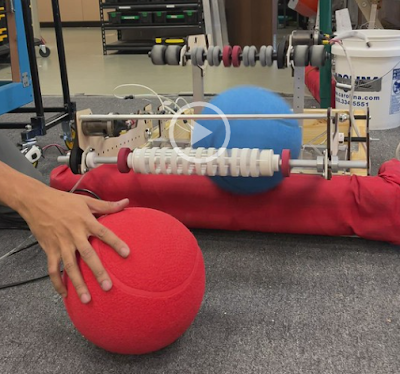

Simple Tests

A lot of our "prototypes" don't need to be complicated to prove concepts. In this quick clip we used part of a prototype from 2020 to see how the balls would behave if we used a timing belt as part of a ball tower.

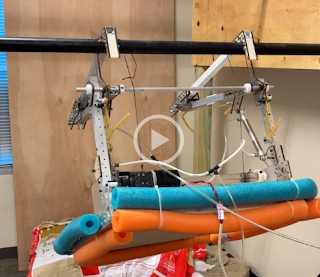

Climber Concepts

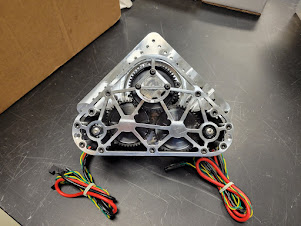

We began working on a new climber concept that uses a double-jointed arm that extends with springs and climbs with a winch. The geometry of this climb appears to work better than some of the others we were working on.

We spent time today mocking it up with laser-cut parts and 3D printed connectors. The 2 extra CIMs are just for ballast to simulate the center of mass of the actual robot.

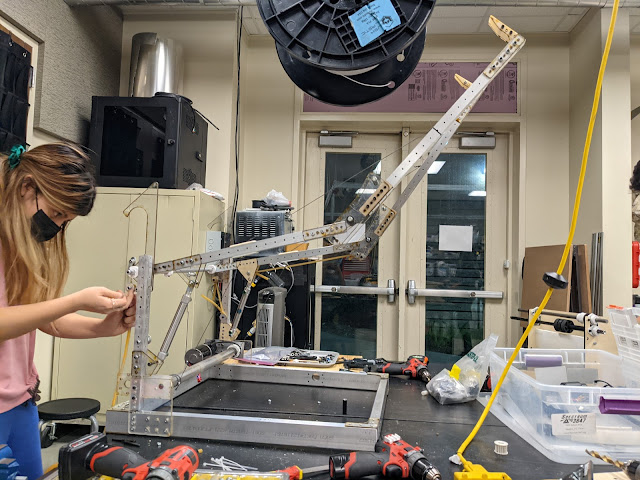

We were able to complete the construction of our practice hangar and run the prototype on it. One of the first attempts with the prototype went one of the more predictable ways.

We will rebuild it this weekend with lessons learned (more perimeters in the prints, more gussets, and bolts/rivets into the tubing) and hopefully future attempts will be more successful. Failures like these are to be expected while prototyping, this is why we often use scrap material or cheap and quick-to-make parts like the 3D printed tube connectors and shaft collars. Failing quickly is one of the best ways to get a robust system in your final robot.'

- Spectrum