The FRC Season is fast approaching, and it's time to start preparing. The priority list window for FIRST Choice round 1 has started, and every team should have their lists submitted by Dec 1st.

Spectrum has prepared a few documents that can help you set up your Priority list and use your Virtual Kit of Parts Vouchers.

Wednesday, November 23, 2022

2023 Spectrum FIRST Choice & Voucher Recommendations

Wednesday, March 9, 2022

Dripping Springs District Recap

We are thrilled to be the 2022 Dripping Springs District Winners with 6800 Valor and 5503 Smithville Tiger Trons.

A big thank you to 6800 for picking us to be on your alliance, you all have an awesome team and robot this year. Thank you to 5505 for joining us and being a great alliance member, your driving skill made our alliance so much better.

Infrared Mechanism Notes from the Event

1. Drivetrain - The SDS MK4i modules worked extremely well, we swapped 5 wheel treads during the event due to wear and cuts/delamination which is better than we experience with the MK3s at the Texas Cup event this past summer. Other than adding grease (we use PTFE) the swerve modules were maintenance-free.

2. Intake - The intake performed very well, the floating roller was able to precisely pick up the cargo we wanted and do so quickly. We have a 3D printed pneumatic cylinder clevis break that we swapped with a metal one but that was honestly to be expected. The belt slipped off the pulley a few times but the design doesn't allow to fully come off so the intake continues to work, we will reprint that pulley slightly wider and possibly increase the flange height to prevent this in the future.

3. Ball Path - The ball path indexer and feeder rollers were pretty much maintenance free they just worked all competition. We clean all our rollers with simple green between matches to remove hair and dust and that's all we had to do to keep these systems working.

4. Launcher - We were running a very simple launcher software with two hood positions and wheel velocities one for the tarmac line shot and one for the fender shot. The fender shot worked on the practice field but wasn't working well on the real field so we abanded it and basically ran fixed hood, single velocity the rest of the event. We had one big launcher issue where the belt to the hood came off and destroyed its pulley, so we had to replace it, we also printed some upgraded pulleys at the event (we bring a Prusa mini with us) but never needed to install them. We also discovered after the event one of the printed pulleys on the falcon wore down a lot and should have been replaced at the event but it didn't affect our performance much.

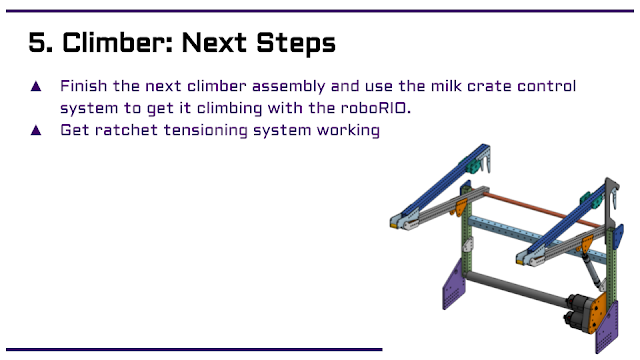

5. Climber - As expected our climber needed the most help during the event. We identified some issues when we tested the climber with the full robot weight compared to our test chassis (weighs ~85lbs). We were able to install larger (1 1/16") bore cylinders and change the strap path to the spool to fix these issues before the event but there were still some tuning to do. The winch strap wasn't wrapping consistently so we had to disable soft limits to ensure we could reach the rear latches each time and we were tuning the motion magic distance values to automatically unwind and wind the winch, once we got those working Saturday afternoon the climb we relatively consistent and we could high bar as needed. We believe the traversal would have worked as well but we were never in a situation where the extra 5 points were needed and it was never worth risking the RP and in the playoffs, the extra points wouldn't have affected the match outcome.

6. Controls - we were running a pretty limited software setup for this event. Our autonomous mode was just timed-based driving (using the velocity loop on our swerve drive) and simple command groups for the double ball auto. The launcher was a feedforward + PID loop to a single velocity for the tarmac line shot. Limelight tuning was set up during the field calibration window before the practice matches and needed to be pretty different from our home setup due to lighting and we used the smart target group feature for the first time. Motion Magic was used on the climb to make it easier to control. We didn't have any electrical or controls issues throughout the event.

Scouting/Strategy Notes

4063 3847 8507

■■■■Qual 49■■■■

4734 7521 3834

- We have 4063, focus on balling out and high climb for 4 rp

- Expect defense from 3834

- They have a double mid-climb + 1 low goal scorer

This gives our drive coach enough information to go to the prematch strategy meeting before each match to make a plan for our alliance.

Photos and Videos:

Spectrum Dripping Springs Photos - Dripping Springs teams feel free to use these photos for any team promotion, etc.

Spectrum 2022 Dripping Springs Match Videos

Tuesday, February 22, 2022

2022 Week 6 Recap

Week 6 Design Recap

Intake Testing

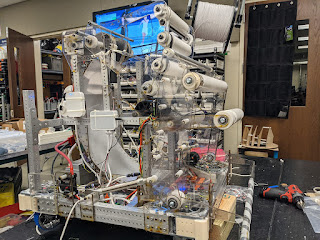

Climber Testing

More progress photos

- https://photos.spectrum3847.org/2022-FRC-1/2022-Build-Season-1/Week-7/Tuesday, February 15, 2022

2022 Day 36: Climber Test and Practice Bot Progress

Climber Test Video

Here is our latest climber test video from this weekend. We still have several tweaks to do but it is working well. This is climbing with around 80lbs and conservative current limits on the two falcons (40A) and being cautious with the control input.

Practice Robot Progress

We were able to get the practice robot near-complete (it won't have a climber until later in the season if at all). We should have some launcher and driving video in the next few days. We happen to have built our 2022 robot to same dimensions as our 2021 robot, so we are using a pair of 2021-8515 bumpers to test on the practice robot, this robot will be 3847.

Friday, February 11, 2022

2022 Day 32 & 33: Build Progress

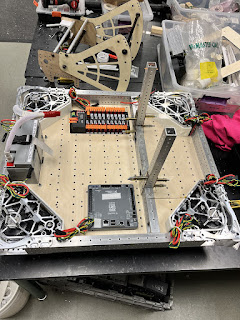

Our CNC router, laser cutter, lathes, and 3D printers have been getting used a lot this week turning out parts for the practice robot.

- Spectrum

Wednesday, February 9, 2022

Sunday, February 6, 2022

2022 Day 29: CAD Updates

We have been working on completing the CAD model of our robot the past few days. We still have a few things to add (intake roller and modifications, the main 4" wheel in the ball path, and ball path funneling) but it's very close to complete.

The full CAD is available here: 0. Infrared 2022 (Top Level Document)

Current Design Specs

- Size: 24.5 x 27.5

- Motors: 15 Falcons: 8 drive, 1 intake, 2 ball path, 2 launcher, and 2 climber (space for 4), 2 Linear servos

- Pneumatics: Intake, and climber, we may add a physical stop to the ball path with pneumatics.

Thursday, February 3, 2022

Everybot Alternatives, Changes, and Checklist

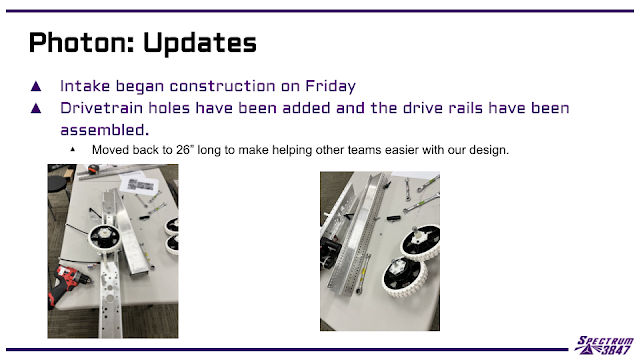

Photon 8515 is building an Everybot

Before we link to the documents we have a couple disclaimers. Please head these warnings, it is recommended that most teams follow the Everybot Build Documentation as closely as possible to replicate the result they showed in the reveal video.

Alternatives

- The listed alternatives are all options that may work but haven’t been tested.

- These are most useful if you already have some items on hand and would like to use them without ordering new things due to budget constraints.

- You will likely need to make other modifications to the build instructions, other parts of the robots, software, etc if you use any alternatives that aren’t listed in the official Everybot BOM. The Everybot team nor Spectrum will be able to support many of these possible alternatives.

- Don’t make substitutions unless you are confident you understand the other changes needed to the design.

Fabrication Ideas

- None of these changes have been tested and they are not recommended by the Everybot team.

- If you choose to make them you likely won’t have support from them since they don’t know how they are supposed to work.

- These changes are thoughts that Spectrum mentors and alumni believe may improve the Everybot 2022 and make it easier for our new students to build. We won’t know for sure until we complete the build which won’t be for many weeks.

Tuesday, February 1, 2022

2022 Day 22, 23, & 24: Design Recap

Day 22: Bootcamp Build Day 2

We had 5 young FRC teams from the Houston area in our lab to help them get their drive trains started and talk to them about the Everybot design and what they need to do to produce it.

Day 23: Intake/Ball Path

As we show below in the design recap the intake and ball path system was in heavy development the past few days. We had a lot of detailed requirements on how we wanted to make the intake function and getting all those requirements packaged into the robot and functioning nicely wasn't going to be easy. Early on we assumed we'd have a multi-roller deployable intake similar to our 2020/2021 intakes and many of the ones we have seen by other teams. Last week we realized we could base our intake off our 2019 and it would allow us to have our intake not extend as far out of the frame and still let us meet our other intake objectives. The test setup we made this weekend confirmed the single intake roller with a kicker bar deployed on the bumper would bring the ball up onto the bumper nicely but there was a potential dead space before the ball would hit our ball path rollers.

Through conversation, we were able to figure out that flipping out another ball bath roller that stays above our bumper so we can confidently leave it deployed all match will solve the dead space issue, prevent unwanted balls from entering our robot, and allow us to eject balls with the intake down.

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)