Priority List

We completed our initial priority list of tasks for the 2023 game.

Cones from the shelf or the floor.

From what we have seen, we are currently a lot lower ground pick of cones than many other teams. Here are a few reasons that we discussed today.

The cones can’t easily roll much further than the wall when dropped onto the floor from the loading stations, so you don’t have much of a cycle distance advantage over taking it off of the shelf.

Intaking the cones from the various orientations and positions against the walls will be very difficult. We don’t believe it will be faster than loading from the known positions on the shelf, especially with the possibility of vision-guided aiming at the loading station.

The Human Player shelf is just a bit higher than the middle cone node, so you don’t need to raise or lower it to be able to place it on the midsection. And for the top, you only have to raise it about a foot and extend it about a foot more than the mid. Much easier than also needing to reach the floor with your cone mechanism.

You can have a specific cube(ball) intake on the ground level and don’t have to potentially compromise your robot's ability to intake cubes(balls) also to pick up cones rapidly.

15 scoring locations out of 27 can be cubes which is more than half.

Each alliance has 27 cones, so if you drop one, you can always return and get another to fill the 12 required spots.

Any dropped cones while attempting to score on a mid or top row will land in the bottom row. If you are strategic about when you score the bottom row, your mistakes may still count for points.

Potential Alliances composition at Districts and Worlds

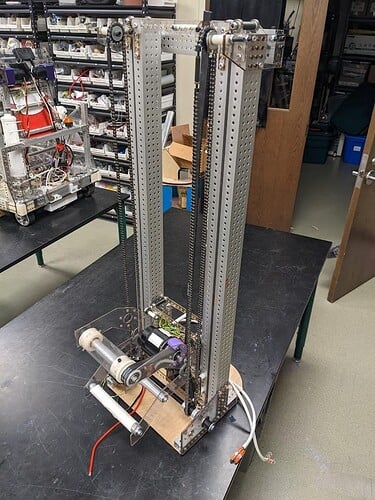

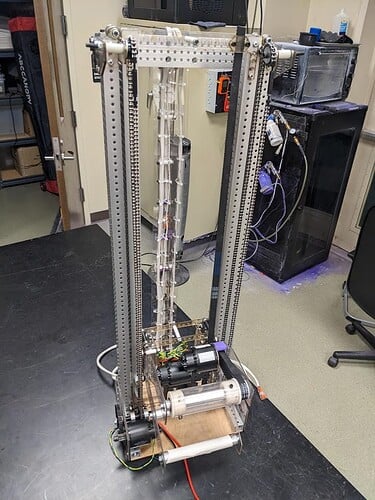

Cube Intake and Launching Prototype

Robot Inspiration

33 in 2012 - Stinger and other 2012 team’s bridge balance aids

1678 in 2019 - Double robot lift for the end game (wouldn’t need to climb)

148 - 2011 - 4 Bar Arm - Arms are potentially useful in this game

1684 - 2019 - Separate intake from elevator scoring mechanism. Doing this for the cubes(balls) will give you a wider intake for picking up the cubes(balls) from the floor.

Tilted/Angled Elevators from 2018 - 2056, 1731, and a few other teams had slightly tilted elevators that let them reach out of the frame while extending up.

Game Comparisons

Logomotion - 2011 - tic tac toe near side

Driver training will be similar.

Rebound Rumble - 2012 - End Game

Balancing on the bridge

Steamworks - 2017 - Cycles and non-symmetric field

Autonomous and cycles will be different depending on which alliance you are.

DDSPBTBC - 2019 - Multi-Game Piece

Cubes roll like cargo, and cones behave like hatch panels.

Power Play (FTC) - 2022

Picking up Cones